Hydraulic System Design

Fig-1

Hydraulic systems can generally be broken down into various types of systems based upon the primary application. For example, on an earthmoving machine, the Primary objective of the hydraulic system is to transmit power efficiently to the various circuits of the machine.

On the other hand, a machine tool application is primarily concerned with speed, accuracy, and stability of the hydraulic systems. Once the design goals are established for a given hydraulic system, the actual design Process can be initiated.

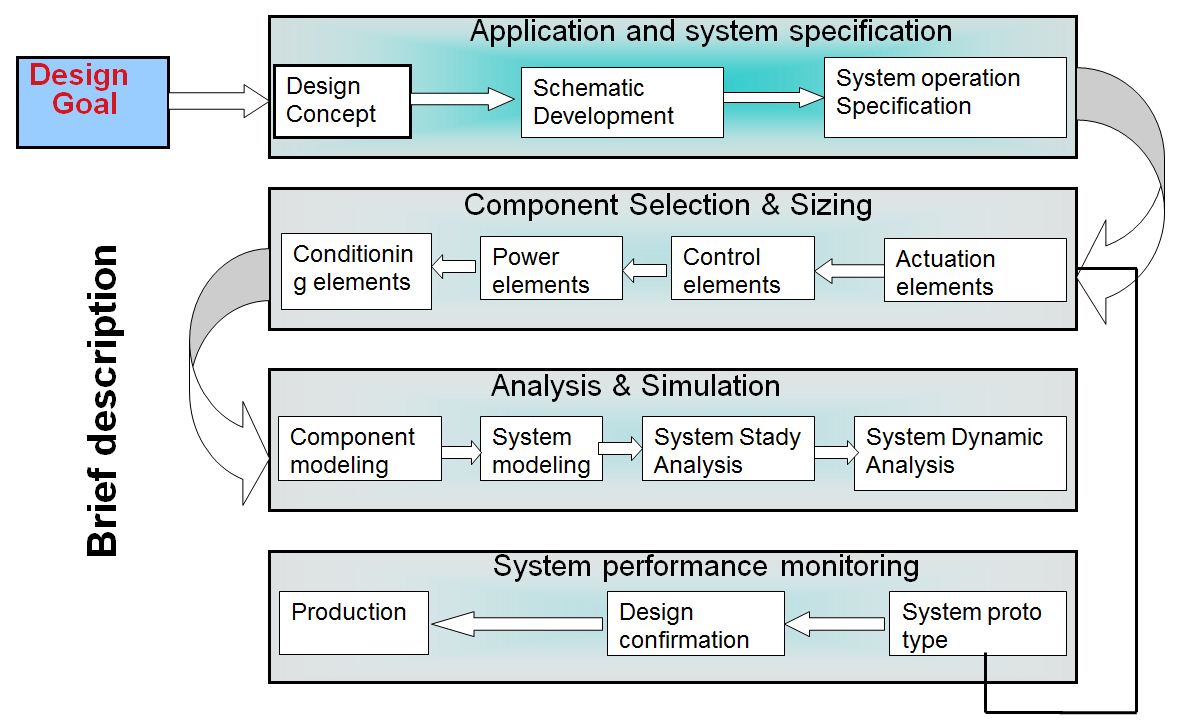

The generalized hydraulic system design and analysis process is illustrated in Fig. 1. From the design goals, the design concept to be integrated into the hydraulic system must be established and a system schematic must be developed along with the operational specifications for the system.

Once these tasks are completed the designer will get into component sizing and selection process. Generally when the sizing and selection phase was completed, the components would be purchased and a proto type system constructed.

The system performance was not simulated and the success of a particular system was mainly a result of the experience of the designer past experience. The actual performance characteristics were evaluated through laboratory and field tests using the system prototype.

Optimization was a function of a process which was normally called "cut and try". This optimization mostly applicable for existing product thru Value engineering project.

Mohammad Arif, ME, MIET(UK), CEng